Antiviral fabrics: mitigate COVID-19 contagion in public spaces

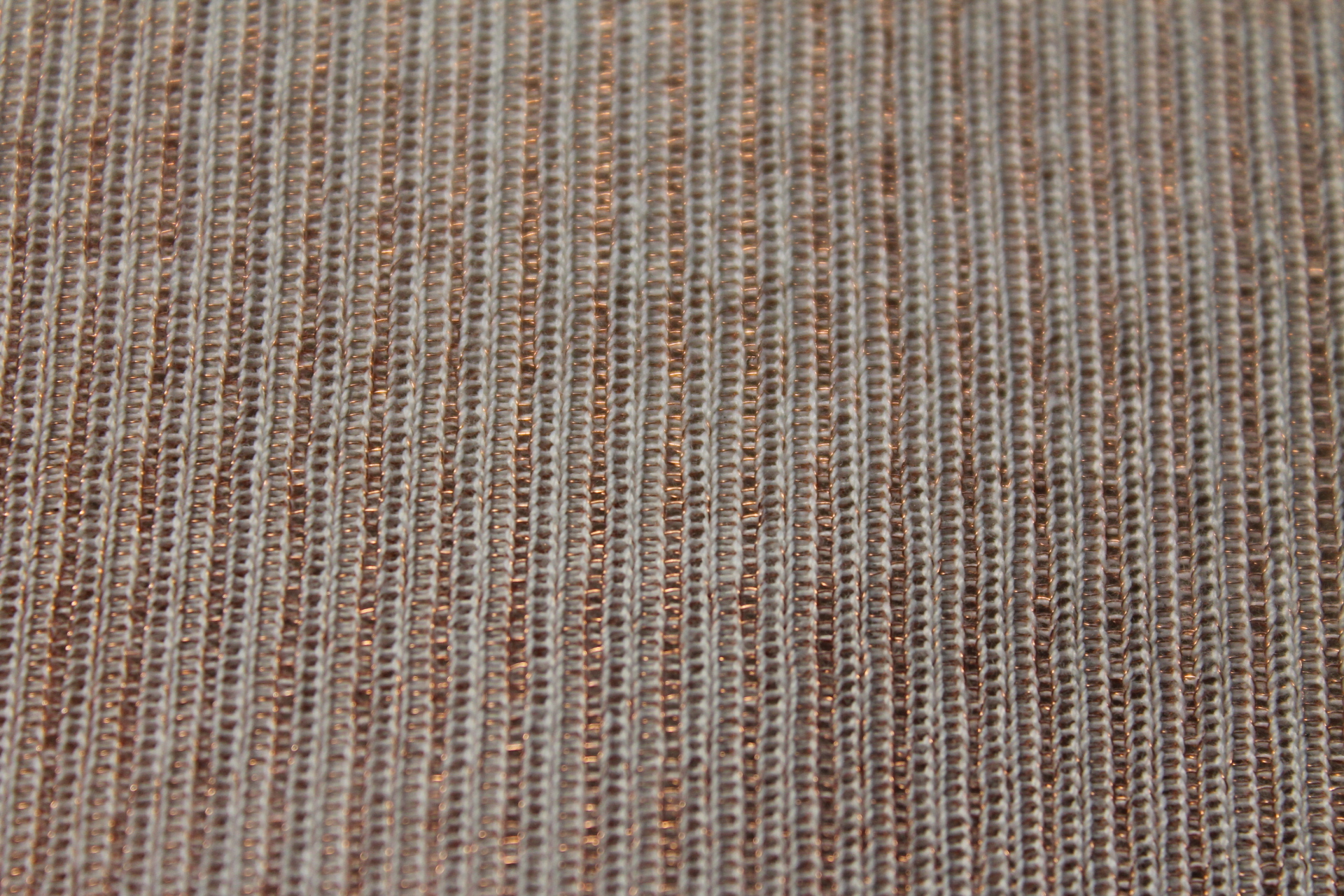

We want to create a fabric that can be hung in restaurants and public spaces to intercept and neutralize infected aerosol and therefore mitigate the spreading of COVID-19 infection.

Firenze, FI Italy Community COVID-19 WarOnCOVID challengeAbout our project

The problem we solve: Academic literature shows that contamination can easily happen in restaurants, when people take off their masks to eat and contaminated aerosol can be airborne to surrounding tables https://wwwnc.cdc.gov/eid/article/26/7/20-0764_article. This study shows how one single person infected 10 people of three different families, all dining out in the same restaurant room.

About our solution: Other academic literature https://www.nejm.org/doi/full/10.1056/NEJMc2004973 shows that copper represents a hostile environment for the virus. We want to limit the spreading by intercepting fluctuating and potentially contaminated aerosol by means of curtains hanging from the ceiling. The curtains will intercept the aerosol and their high content of copper (70% min content) will neutralize SARS-CoV-2 in a short time.

Progress to date:

We have prototypes of fabrics, two currently under test at the university of Cagliari for ISO20743 standard compliance. We are in contact with the Viral Lab of the University of Cagliari directed by prof. Tramontano (https://corsi.unica.it/sciviamfa/people/phd-board/enzo-tramontano/) to test the same fabrics for antiviral properties. We strongly believe this solution will have a big impact on restaurants and public spaces if we'll be able to demonstrate that by adding this type of fabrics in a room, restaurants will be able to increase the number of people in their dining rooms without increasing the possibility of contagion.

As at today the first test according to ISO20743 gave exceptional results: the standard indicates a scale from 1 to 3, where 1 is a fabric with poor antibacterial effect and 3 is good. Our fabric performed 6. We are continuing with more tests with bacteria and SARS-CoV-2.

About Our Team

Creator: Riccardo Marchesi

Location: Firenze

Education: University of Firenze

Bio: Riccardo Marchesi - BIO Current position CEO Texe srl – Italy CEO Plug&Wear srl - Italy Brief biography From 2001 Riccardo Marchesi is Managing Director of Texe srl. Just after his graduation he joins the family company, SCOMAR srl producing flat knitting machines, as International Sales Manager. From 1987 to 1999 he develops the sales in the US market bringing the company to become the first supplier of collar flat knitting machines in America.. From 1992 he is also responsible for new developments on machines. With the repositioning of the textile industry in the Far East and the consequent closure of the knitting manufacturing plants in Europe and the US starting from 2000 he transforms the company from a producer of flat knitting machines to a producer of high performance technical textiles, such as metal fabrics for shielding electromagnetic interferences (EMI) and smart fabrics. The deep knowledge of textile technologies and his expertise of textile industrial processes allow him to develop highly innovative solutions for EMI shielding and smart fabrics. His current research activities are in the field of interactive textiles for HCI and robotics. He is the founder of www.plugandwear.com, the first company for industrial textile sensors.

Title: Ing.

Advanced Degree(s): MD

About Our Company

Location: via Rocca Tedalda, 25

Firenze, Firenze 50136

IT

Founded: 1990

Website: http://www.inntex.com

Facebook: https://www.facebook.com/inntex.metal.fabrics/

Other link: https://www.instagram.com/inntex_metal_fabrics/

Product Stage: Prototype/MVP

YTD Sales: $250,000..1M

Employees: 5-10

Challenge Mission

COVID Problem We Address

Our company wants to solve the problem of restaurants and other public spaces where wearing a mask is not practical or it is impossible. The idea is to mitigate the diffusion of potentially infected aerosol (i.e. from sneezing) that will fluctuate in the air in a closed space due to air-conditioning. This can be achieved by using fabrics with a very high percentage of copper and hanging them like curtains to intercept the air stream.

Our COVID Solution

Copper is a material that neutralizes SARS-CoV-2 and other viruses in a short period of time https://www.nejm.org/doi/full/10.1056/NEJMc2004973. Our copper knitted fabrics have holes and they let the air go through. If placed in path of the air flow of the heating system/air conditioning they will capture the small droplets fluctuating in the air. Once on the fabric the potentially contaminated droplets will be neutralized by the presence of copper

Innovation Details

Intellectual Property Summary

We are waiting for the result of the tests to file a patent. Producing copper metal fabrics in any case requires special machinery and special knowledge Our company is in textiles since 1951 and all our machine are built in house.

Clinical Information

Not available yet, waiting for the two labs to give us their results. So far the first result according to ISO20743 standard gave a very good result.

Regulatory Status

We don't think we'll need an FDA clearance as fabric will not be touched by anyone, just hanging from the ceiling.

How we will use the funds raised

We'll use the funds mainly to speed the development and validation process up, for IP and for selling efforts.

Validation process: we would like to test more materials and more production techniques, including novel technologies that seem very effective to neutralize SARS-CoV-2 and other viruses. We expect to spend 40% of funds for buying new materials, making new fabric samples, test them for their antibacterial properties (ISO20743) and antiviral properties. We expect to spend 40% of funds to penetrate the markets, to find distributors, and to advertize our product.

IP: after a deep research on the prior art we'll start by filing a national Italian patent. This will give us time to complete the product, but at the same time to have a priority date. All following patents (US, EU and Chinese) will have the same priority date of the first one.

Thank You

I am an Italian engineer with 35 years experience in textiles. Italy was one of the first Western countries infected by COVID-19. We had a lockdown of two months. I am passionate about innovation and I would be very excited to help people in this difficult period. I believe that for the next two or three years we'll have to live with the virus, but at the same time I think we'll need to start living as we were living before, trying to limit the risks of being infected. My personal competence and the competence of my team in interior design with the possibility of our machinery of producing copper fabrics is definitely a win-win situation.

I thank you in advance for your help.

Updates

-

Update #1

ISO20743 Final report

The University Lab in charge of testing our fabrics issued a report that indicates a very high index of antibacterial activity (6.5 minimum). We are now continuing our tests with Corona Virus. -

Update #2

Update June 26

Our project published on Miami Scientific Italian Community Bulletin https://www.miamisic.org/inntex-antiviral-copper-fabrics-mitigate-covid-19-contagion-in-public-spaces/ -

Update #3

Update June 26

We discovered ISO published a standard to determine the antiviral properties of fabrics. We will perform our antiviral tests according to ISO18184 -

Update #4

Update July 2 - glove test

We have produced a glove with our antiviral fabric. The results can be seen here: http://www.inntex.com/industry/antiviral.asp -

Update #5

Update July 5

We are pleased to announce that a new experienced professional has joined our Team: Dr. Femi Oyedokun is an engineer with a PhD in Petroleum Engineering and a career in fluid mechanics with deep knowledge of air quality in closed spaces.

Supporters

-

07/06/2020 - Liked the project.

07/06/2020 - Followed the project.

07/05/2020 - Liked the project.

07/01/2020 - Followed the project.

06/29/2020 - Liked the project.

06/29/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/28/2020 - Liked the project.

06/27/2020 - Liked the project.

06/25/2020 - Liked the project.

06/23/2020 - Liked the project.

06/23/2020 - Liked the project.

06/21/2020 - Liked the project.

06/20/2020 - Liked the project.

06/19/2020 - Liked the project.

06/18/2020 - Interested in helping your project as a mentor or team member.

06/18/2020 - Followed the project.

06/17/2020 - Liked the project.

06/17/2020 - Liked the project.

06/17/2020 - Liked the project.

06/16/2020 - Backed the project for $1000

06/16/2020 - Liked the project.

06/16/2020 - Liked the project.

06/16/2020 - Liked the project.

Comments

-

Klaus Richter posted on 16th June, 2020

Klaus Richter, Germany. This project meets the actuel needs perfectly. If it works well it is as well good for schools, childrens garden and so an es well. We support this project.

-

Oluwafemi Oyedokun posted on 6th July, 2020

You are right Klaus, it can serve schools and other rooms/spaces with large gatherings... places of worship?

Click here to LoginInstant Feedback

Help us find best new ideas to fund by telling us what you think. Your feedback goes straight to the team behind this project in private, so tell them what you really think.

71Medstartr

Index Score71

Interest

Score0

Adoption

Score32

Likes0

Partners0

Pilots3

Follows-

This campaign has ended but you can still get involved.See options below.

€1,000 pledged of €500,000 goal

Instant Feedback

Help us find best new ideas to fund by telling us what you think. Your feedback goes straight to the team behind this project in private, so tell them what you really think.